Titanium Dioxide

Release Time:

Jul 02,2025

Cosmetic chemists are leveraging micronized titanium dioxide to create next-generation sun care products with improved spreadability and non-whitening effects. Advanced coating technologies allow particles to scatter both UVA and UVB radiation more efficiently, enabling higher SPF ratings without increasing product thickness. The material's biocompatibility has also spurred innovations in medical applications, including antimicrobial surface treatments for healthcare facilities.

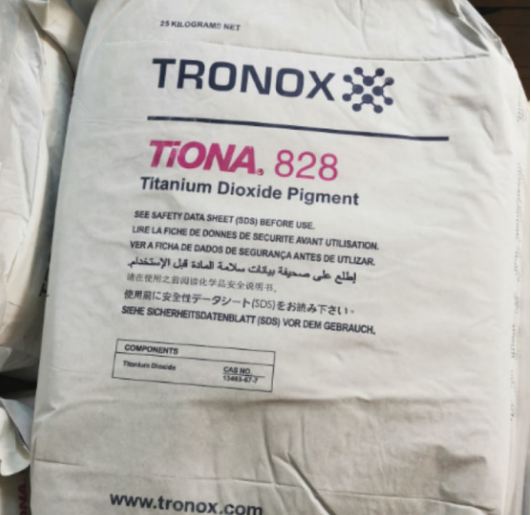

TRONOX® CR-828 rutile titanium dioxide pigment is a universal product with the highest optical properties and good durability for interior and exterior applications. TRONOX® CR-828 provides high gloss, excellent opacity and tint strength, and a clean undertone.

Applications:

Interior and exterior industrial

■ Maintenance coatings

■ Interior and exterior architectural coatings

■ Solvent and water based coatings

Typical Properties1:

TiO2 content, % ....................................... ...................................................................95

Density

Specific gravity .................................... ....................................................................4.1

Bulk ........................ ................................................ 0.8 kg/L or 50 lbs/cu.ft.

Oil absorption............. ......... .................................................................17

pH .............................. ................................ ...........7.4

Specific Resistance, Kohms-cm .................... ........................................8

Average particle size2 , μm..................................................... ...............................0.19

Specification

ASTM D476....................................... ...........................................................Type II, III, VI, VII

ISO 591-1:2000................................................................................................ ......R2

Cosmetic chemists are leveraging micronized titanium dioxide to create next-generation sun care products with improved spreadability and non-whitening effects. Advanced coating technologies allow particles to scatter both UVA and UVB radiation more efficiently, enabling higher SPF ratings without increasing product thickness. The material's biocompatibility has also spurred innovations in medical applications, including antimicrobial surface treatments for healthcare facilities.

Environmental considerations are shaping production methods, with several manufacturers adopting chloride-free processes that reduce energy consumption by 30% compared to traditional sulfate routes. Closed-loop water recycling systems in modern facilities minimize waste, while new photocatalytic formulations help purify air when incorporated into building materials.

As industries increasingly prioritize performance, sustainability, and multi-functionality, titanium dioxide stands out as a material that continues to evolve beyond its conventional roles. From enabling brighter, more durable paints to protecting skin from solar damage, its unique properties remain unmatched, ensuring its position as a cornerstone of modern material science across countless applications that touch everyday life.

Keywords:

You Can Also Learn More About Industry Trends