Understanding Rutile Sand 94%: Applications and Advantages in the Chemical Industry

Release Time:

Jul 02,2025

Rutile Sand 94% is primarily composed of titanium dioxide (TiO2), renowned for its high purity level of 94%. This exceptional purity makes it an ideal candidate for numerous applications across different sectors. Due to its unique properties, Rutile Sand is frequently utilized in the production of high-performance pigments, particularly in paints, coatings, and plastics. The brightness and opacity

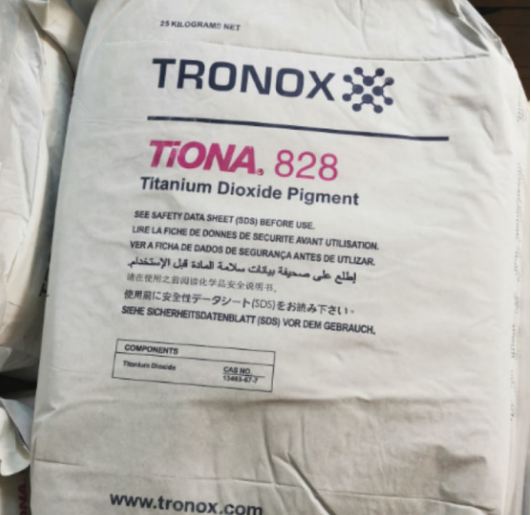

Rutile Sand 94% is primarily composed of titanium dioxide (TiO2), renowned for its high purity level of 94%. This exceptional purity makes it an ideal candidate for numerous applications across different sectors. Due to its unique properties, Rutile Sand is frequently utilized in the production of high-performance pigments, particularly in paints, coatings, and plastics. The brightness and opacity offered by Rutile Sand ensure that products maintain their aesthetic appeal while providing excellent durability.

One of the most notable characteristics of Rutile Sand is its high refractive index, which contributes to its effectiveness as a pigment. Industries involved in manufacturing coatings and paints value this property, as it enhances color intensity and overall product performance. As a result, Rutile Sand 94% is often favored over other forms of titanium dioxide, particularly when a superior finish is desired.

In addition to its use in pigments, Rutile Sand 94% plays a crucial role in the production of titanium metal. The extraction process involves reducing titanium dioxide to produce titanium sponge, which is then utilized in various applications, including aerospace, automotive, and medical devices. The lightweight yet strong characteristics of titanium make it a material of choice for industries aiming to create durable and high-performance products.

Furthermore, Rutile Sand 94% is integral to the manufacturing of ceramics and glass. Its high melting point and chemical stability contribute to the strength and durability of ceramic products, making them suitable for both functional and decorative applications. In the glass industry, the use of Rutile Sand allows for the production of high-quality glass with enhanced clarity and resistance to scratching.

The versatility of Rutile Sand 94% extends to its applications in the production of welding rods and electrodes. Its unique composition provides improved arc stability and reduces spatter during the welding process, thereby enhancing the overall efficiency and quality of the weld.

In summary, Rutile Sand 94% is a vital component in various industrial applications, offering exceptional properties that enhance product performance across multiple sectors. Its high purity, refractive index, and stability make it an invaluable resource for manufacturers aiming to produce high-quality chemical materials. As industries continue to innovate, the demand for Rutile Sand is expected to grow, underscoring its importance in modern manufacturing processes.

One of the most notable characteristics of Rutile Sand is its high refractive index, which contributes to its effectiveness as a pigment. Industries involved in manufacturing coatings and paints value this property, as it enhances color intensity and overall product performance. As a result, Rutile Sand 94% is often favored over other forms of titanium dioxide, particularly when a superior finish is desired.

In addition to its use in pigments, Rutile Sand 94% plays a crucial role in the production of titanium metal. The extraction process involves reducing titanium dioxide to produce titanium sponge, which is then utilized in various applications, including aerospace, automotive, and medical devices. The lightweight yet strong characteristics of titanium make it a material of choice for industries aiming to create durable and high-performance products.

Furthermore, Rutile Sand 94% is integral to the manufacturing of ceramics and glass. Its high melting point and chemical stability contribute to the strength and durability of ceramic products, making them suitable for both functional and decorative applications. In the glass industry, the use of Rutile Sand allows for the production of high-quality glass with enhanced clarity and resistance to scratching.

The versatility of Rutile Sand 94% extends to its applications in the production of welding rods and electrodes. Its unique composition provides improved arc stability and reduces spatter during the welding process, thereby enhancing the overall efficiency and quality of the weld.

In summary, Rutile Sand 94% is a vital component in various industrial applications, offering exceptional properties that enhance product performance across multiple sectors. Its high purity, refractive index, and stability make it an invaluable resource for manufacturers aiming to produce high-quality chemical materials. As industries continue to innovate, the demand for Rutile Sand is expected to grow, underscoring its importance in modern manufacturing processes.

Keywords:

You Can Also Learn More About Industry Trends