Titanium Dioxide

Release Time:

Jul 02,2025

Perhaps most transformative are recent developments in air purification. Urban construction projects increasingly incorporate cement mixtures doped with photocatalytic particles that actively neutralize nitrogen oxides—with testing showing a 30-50% reduction in street-level pollutants. Similar technology is being integrated into HVAC systems, where coated filters simultaneously trap particulates and break down volatile organic compounds.

Product Description:

Ti-Pure® R-902+ is a multipurpose rutile titanium dioxidepigment manufactured by the chloride process for both interiorand exterior coatings applications. It is a fine dry powder withthe following general properties.

| Analysis and Physical Properties ofTi-Pure® R-902+ | |

| Property | R-902+ |

| TiO2,wt%,min. | 93 |

| Alumina | yes |

| Amorphous Silica | yes |

| Specific gravity | 4.0 |

| Bulking Value,L/kg(gal/lb) | 0.25(0.03) |

| Organic treatment | yes |

| Color CIE L* | 99.6 |

| Median Particle Size,μm | 0.405 |

| Oil absorption | 16.2 |

| pH | 7.9 |

| Resistance at 30℃(86°F)(1000 ohm) | 8.1 |

| Carbon Black Undertone | 11.7 |

Suggestions for Use:

Ti-Pure® R-902+ has an excellent balance of chalk resistance,hiding, and gloss with outstanding dispersion performance fora broad range of both exterior and interior applications. Ti-Pure®R-902+ is recommended for use in:

• architectural interior semigloss and exterior finishes

• exterior industrial finishes, except those that require thehighest level of exterior durability

• powder coatings

Safety Precautions:

• Titanium dioxide is classified as a nuisance dust. Followall local regulations and DuPont recommendations forexposure limits as described in the Material Safety Data Sheet(MSDS). If the recommended exposure limits of TiO2 are tobe exceeded, NIOSH-approved air-purifying respirators withparticulate filters should be used.

• As a matter of good industrial hygiene, gloves and safetyglasses with side shields or better eye protection should beworn when handling TiO2. For more details, refer tothe MSDS.

First Aid:

• If large amounts of TiO2 are inhaled, remove victim to freshair. If not breathing, give artificial respiration. If breathing isdifficult, give oxygen. Call a physician.

• In case of eye contact, immediately flush with water for atleast 15 minutes. Call a physician.

• In case of skin contact, the compound is not likely to behazardous, but cleaning the skin after use is advised.

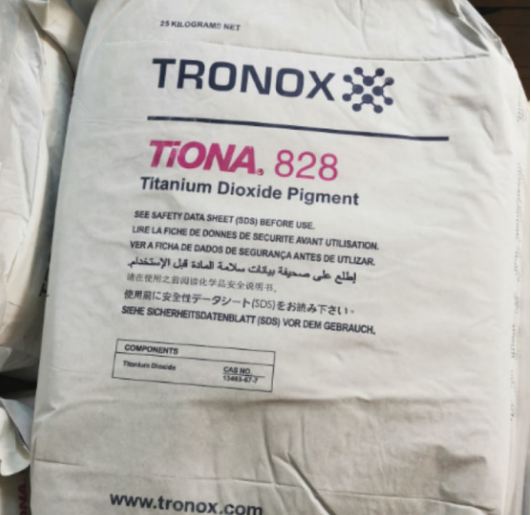

Shipping Containers:

Ti-Pure® R-902+ is available in 25-kg paper bags and1 metric ton flexible intermediate bulk containers. Truckloadshipments of the dry product are available directly from DuPont.Less-than-truckload volumes are available through one of theauthorized DuPont distributors.

A slurry offering is available in some regions in truckloadshipments (15 metric ton) and railcar (67 metric ton).

Product Storage:

The shelf life of DuPont™ Ti-Pure® TiO2 is indefinite as long asthe material is kept from direct contact with moisture.

Perhaps most transformative are recent developments in air purification. Urban construction projects increasingly incorporate cement mixtures doped with photocatalytic particles that actively neutralize nitrogen oxides—with testing showing a 30-50% reduction in street-level pollutants. Similar technology is being integrated into HVAC systems, where coated filters simultaneously trap particulates and break down volatile organic compounds.

The material's biocompatibility has opened doors in unexpected areas. Dental composites now utilize precisely sized particles that mimic natural tooth opacity while providing superior wear resistance. Textile engineers have created sun-protective fabrics that retain breathability despite blocking 98% of UV radiation, a boon for outdoor workers and athletes.

As production methods evolve to meet stricter environmental standards, the next generation of titanium dioxide products promises even greater functionality. From smart windows that adjust transparency to water treatment systems that harness solar energy for purification, this versatile compound continues to demonstrate why it remains one of material science's most valuable tools—adapting to meet the challenges of our changing world.

You Can Also Learn More About Industry Trends